Speed:50000CPH,

PCB Size : 800 mm ×370 mm,

Feeder input:112pcs,

Weight: 1630KG

JUKI RS-2 Pick and Place Machine

Specifications:

JUKI RS-2 Pick and Place Machine

The RS-2 is a next-generation SMD pick and place machine. It is engineered for high-speed, precise component placement in electronics manufacturing. This advanced automated placement system processes from small 03015 chips to large components up to 50 mm x 150 mm. Moreover, the RS-2 supports up to 112 feeders and reaches 50,000 CPH. It delivers excellent flexibility, efficiency and speed for your SMT line.

Thanks to its versatile capabilities and minimal changeover times, this pick and place machine for SMD is ideal for both high-mix and high-volume production environments. At the heart of the system is the revolutionary TAKUMI head, which adjusts automatically to various component heights, ensuring fast, accurate placements without compromising speed or performance. In addition, multiple RS-2 machines can be combined into flexible SMT pick and place solutions, offering a scalable setup for advanced production requirements.

Key Features of the RS-2 SMD Pick and Place Machine:

TAKUMI head technology: The advanced 8-nozzle head features adaptive height sensing, covering the full component spectrum – from 0,3 × 0,15 mm (03015) chips to components up to 50 × 150 mm. It automatically adjusts reference heights and optimises Z-axis movements for faster cycle times.

Modular and scalable architecture: The RS-2 integrates effortlessly into existing SMT production lines. Additional machines can be added with identical setup, operation, and spare parts – enabling efficient and cost-effective line expansion.

Low maintenance requirements: Engineered for reliability, the RS-2 features a durable construction and automated calibration, reducing service needs to a minimum. Annual maintenance time per machine is less than 20 hours.

Optimised line performance: The RS-2 enables seamless placement of mixed components without the need for head changes or retooling. This ensures continuous operation, minimal downtime, and consistently high throughput.

Why the TAKUMI Head Is Revolutionary:

Built-in laser sensor: Integrated laser sensor recognises components “on the fly” during movement for real-time identification and precise placement.

Adaptive height adjustment: The sensor automatically adapts to each component’s height, ensuring minimal movement and stable cycle times.

Flexible calibration system: The optional FCS adjustment tool enables accuracy checks after facility relocation or as the equipment ages. If adjustments are required, automatic corrections can be performed, ensuring stable placement accuracy and reducing maintenance effort.

Universal placement head: No head change required – the TAKUMI head handles the entire range of components from 03015 up to large QFPs. Multiple RS-2 machines can be configured and operated within a single production line. This simplifies line planning, reduces setup time and increases overall line throughput.

Main Functions of the RS-2 SMD Pick and Place Machine:

Verification Camera System

The RS-2 ensures precise optical alignment of components using a VCS camera system that detects shapes, leads, and solder balls – even on complex components like QFPs and BGAs. This enables in-line inspection for defects such as bent leads or missing solder balls.

The 360° recognition capability compensates for unstable or misaligned components by automatically adjusting the placement angle. A multi-colour lighting system (red, green, blue) dynamically adapts to the material and geometry of each component, improving contour recognition and ensuring stable, high-precision placement.

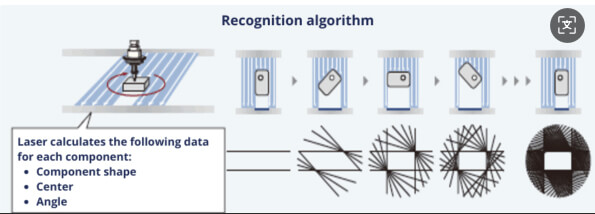

Laser Geometry Recognition

JUKI’s laser-based component recognition system identifies the shape, centre position, and rotation angle of components in real time as they move towards the placement position. This precise geometric analysis enables stable placement across a wide component range – from 03015 chips to QFPs up to 50 mm.

Operating independently of shape, colour or surface reflectivity the system ensures high recognition reliability for all component types. Misplaced parts, including defects such as tombstoning – are automatically detected for rework or rejection. This enhances overall process security and enables fast integration of new components through automatic data generation.

Auto Cueing

Smart automation supports operators during setup and production start. The auto-feeding function loads and positions new component tapes at the first pick location during reel changes. This minimises setup time and enables fast SMT manufacturing.

Сoplanarity model

An integrated coplanarity module detects planarity defects such as lifted leads on ICs or deformed solder balls on BGAs. Faulty components are identified before placement and excluded from the process, enhancing overall production reliability.

Flexible Vision Teaching & Automatic Component Measurement

New components can be registered quickly and accurately. Using laser measurement and camera-based detection, the system automatically identifies pin count, geometry, and outline. The user-guided software generates all required recognition parameters, while laser sensors measure height and width. This significantly reduces programming time and ensures seamless integration of new parts – ideal for high-mix production environments.

IC Collection Belt

Defective or unplaced components are safely collected without damage and stored for the analysis, reducing manual intervention.

RS-2 SMD Pick and Place Machine – All Benefits at a Glance

Maximum efficiency with minimal downtime: Innovative functions such as auto cueing, automatic component recognition and the adaptive TAKUMI head reduce changeover times and maintain a consistently high throughput rate.

Outstanding flexibility: Modular design allows easy expansion, shared spare parts and standardised operation across

multiple machines – scalable for both high-mix and high-volume manufacturing.

Industry 4.0 ready: Full traceability and data connectivity make the RS-2 an ideal choice for smart, digital production environments.

Process reliability through smart automation: Core functions such as component recognition, nozzle selection, automatic calibration and quality checks are fully automated – significantly reducing operator workload and eliminating potential sources of error at an early stage.

JUKI RS-2 Pick and Place Machine | |||

PCB | Min | 50 mm ×50 mm | |

Max | 1 clamping | 800 mm ×370 mm | |

3 clamping | 410 mm×370mm | ||

PCB Weight | Max 3kg | ||

PCB thickness | 0.3~6.0mm | ||

Component height | 25 mm | ||

Component size | 03015~50mm×150mm(1×3 spot)□74mm(2×2 spot) | ||

Placement speed | Best Condition | 50,000CPH | |

IPC9850 | 32,000CPH | ||

Placement accuracy | ±35μm(Cpk≧1) | ||

Feeder capacity | 112 *1 | ||

Power | 3 phase AC200V /AC200V~415V | ||

Apparent power | 2.2 kVA | ||

Air pressure | 0.5±0.05 MPa | ||

Air consumption | When using a vacuum generator: 200 L/min (standard); when using a vacuum pump: 50 L/min (optional). | ||

Machine Dimension (W×D×H) *2 | 1,500 mm ×1,686 mm ×1,450 mm | ||

Machine Weight | About 1,630kg | ||

Keywords:

JUKI RS-1R Pick and Place Machine, JUKI RX-7R Pick and Place Machine, JUKI RX-8 Pick and Place Machine, JUKI RS-1R SMT Assembly Line, JUKI RX-7R SMT Assembly Line, JUKI RX-8 SMT Assembly Line.

Contact: Tommy

Phone: +86 13691605420

E-mail: tommy@flason-smt.com

Add: No.94,Guangtian Road,Songgang Street,Bao an District Shenzhen China